Addressing Water Risk

Water Consumption Reduction Targets and Risk of Water Shortages

We believe that the effects of climate change will typically appear in water, so OKI is preparing for the risk of water shortages in future. We have implemented water management plans at five sites in Japan and two overseas, targeting those that use 100,000 m3 or more of water per year in Japan and water-stressed areas outside Japan.

| Water status | Site | Targets and initiatives |

|---|---|---|

| Water consumption (100,000 m3 or more per year) |

OKI Nishiyokote OEC OSC OTC Niigata OTC Yamagata |

The water consumption target we set for the Group as a whole in FY2022 is an absolute reduction of at least 0.2% compared to FY2021. We plan to continue setting targets and working to reduce water consumption in future. |

| Water stress (high) | ODMT ODMT-3 |

Water consumption at the Rojana Industrial Park, where ODMT is located, is limited to 83,000 m3/day for all factories there. For that reason, ODMT is working to reduce water consumption as an ISO 14001 initiative. It is working toward a specific target of reducing water consumption per hour by 4%. One measure is the reuse of water from the cafeteria cleaning equipment. |

Water stress is defined as a situation where the baseline water stress in the Aqueduct Water Risk Atlas is assessed as “high” or greater. Assessments happen regularly.

Initiatives to Reduce Water Consumption

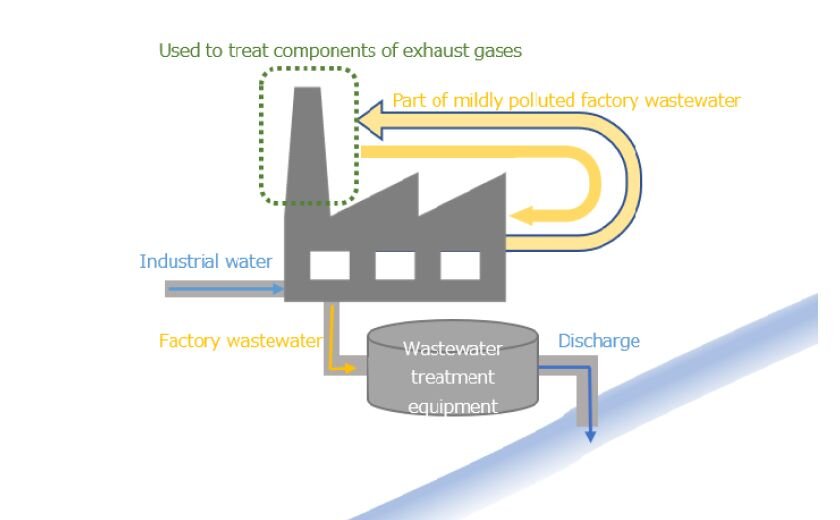

Some production processes at OKI Circuit Technology’s main factory generate an acidic mist, resulting in acidic vapors. Acid-cleaning scrubbers remove harmful acidic components. The acid-cleaning scrubbers reuse mildly polluted wastewater from production processes as cleaning water for removing harmful components. This method recycles about 4,000 m3 of water yearly. Acidic components adsorbed by the scrubber cleaning water are detoxified in the wastewater treatment process and discharged to the sewage system.

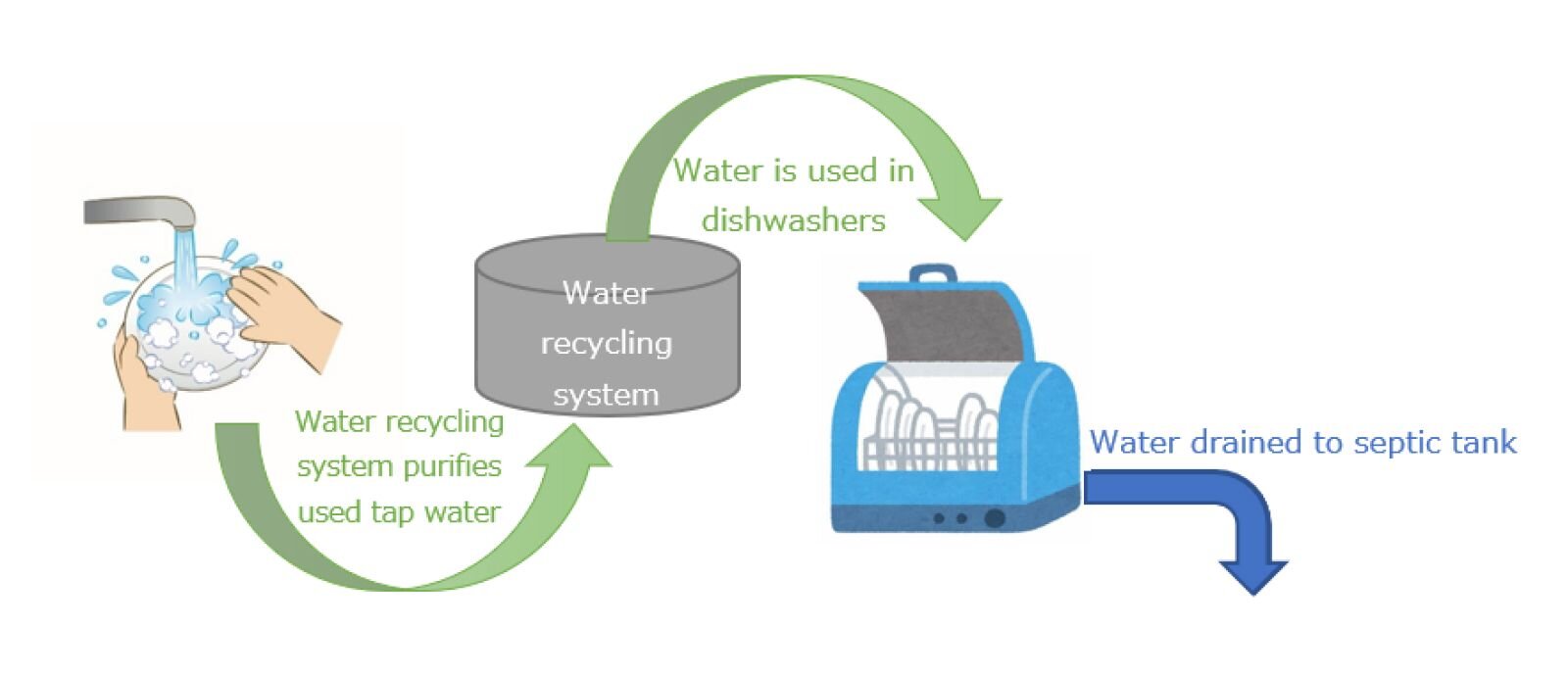

OKI Data Manufacturing (Thailand) (ODMT) recycles the water used in its dishwashers. Previously, dishwashing consumed 800 to 1,000 m3 of water each month. ODMT has been able to reduce water withdrawals by about 310 m3 per month by using a water recycling system installed in FY2023. The Rojana Industrial Park in Thailand, where ODMT’s factory is located, restricts water withdrawals, so we are working to reduce water consumption as far as possible.

Basic Initiatives for Factory Wastewater

Wastewater from our factories and offices is discharged only after it has been detoxified, in accordance with national laws. We analyze the discharged water periodically to ensure that we are maintaining appropriate conditions. Some factories handle heavy metal ions, but we remove these by wastewater treatment before discharging the water. We monitor our operations appropriately day to day to ensure that we are not impacting people’s lives or creating health problems.