- Home

- Innovation (Yume Pro)

- Activity Examples in Focus Areas

- Logistics

Activity Examples in Focus Areas

Logistics

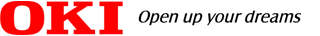

OKI aims to expand the business by solving the most pressing market entry logistics issues.

OKI's goals in the logistics field (transportation x warehousing)

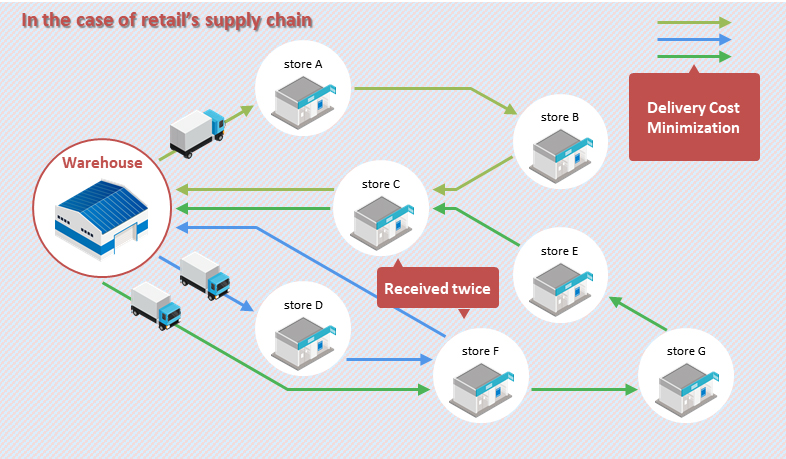

Increasing the sophistication of logistics operations for transportation and warehousing through the overall optimization that connects on-site AI edges and bases.

- Expanding the optimization of branch line transportation to the trunk line transport by "optimal loading" x "optimal delivery route"

- Supporting the resilience of the entire supply chain (BCP:Business Continuity Planning) with the on-site IoT and the mechatronics/automated transportation technology

- Participating in standardization activities both domestically and internationally. Expanding the global business with standards-based solutions

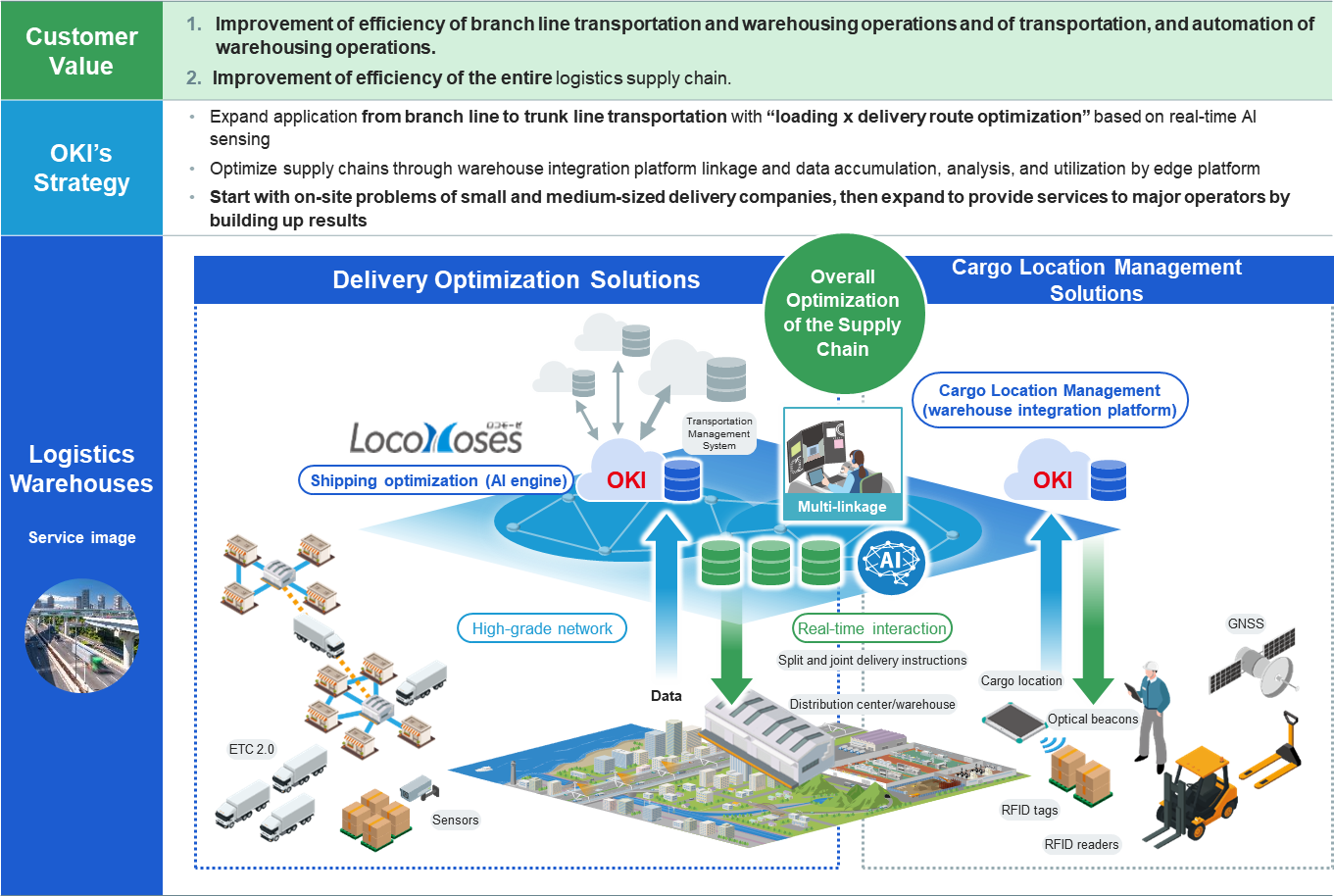

Steps to enter the business in the logistics field (transportation x warehousing)

Business entry will be implemented in the following three phases through OKI technology and co-creation with partner companies.

- Phase 1

- Real-time sensing and automatic transportation technology ⇒ Visualization and individual efficiency of transportation/warehousing

- Phase 2

- Cross-industry integrated data ⇒ Branch line joint delivery & warehouse virtualization ⇒ Cross-sectional efficiency of transportation x warehousing

- Phase 3

- Transportation x warehousing integrated PF and digital twin ⇒ Real-time overall SC optimization of transportation x warehousing

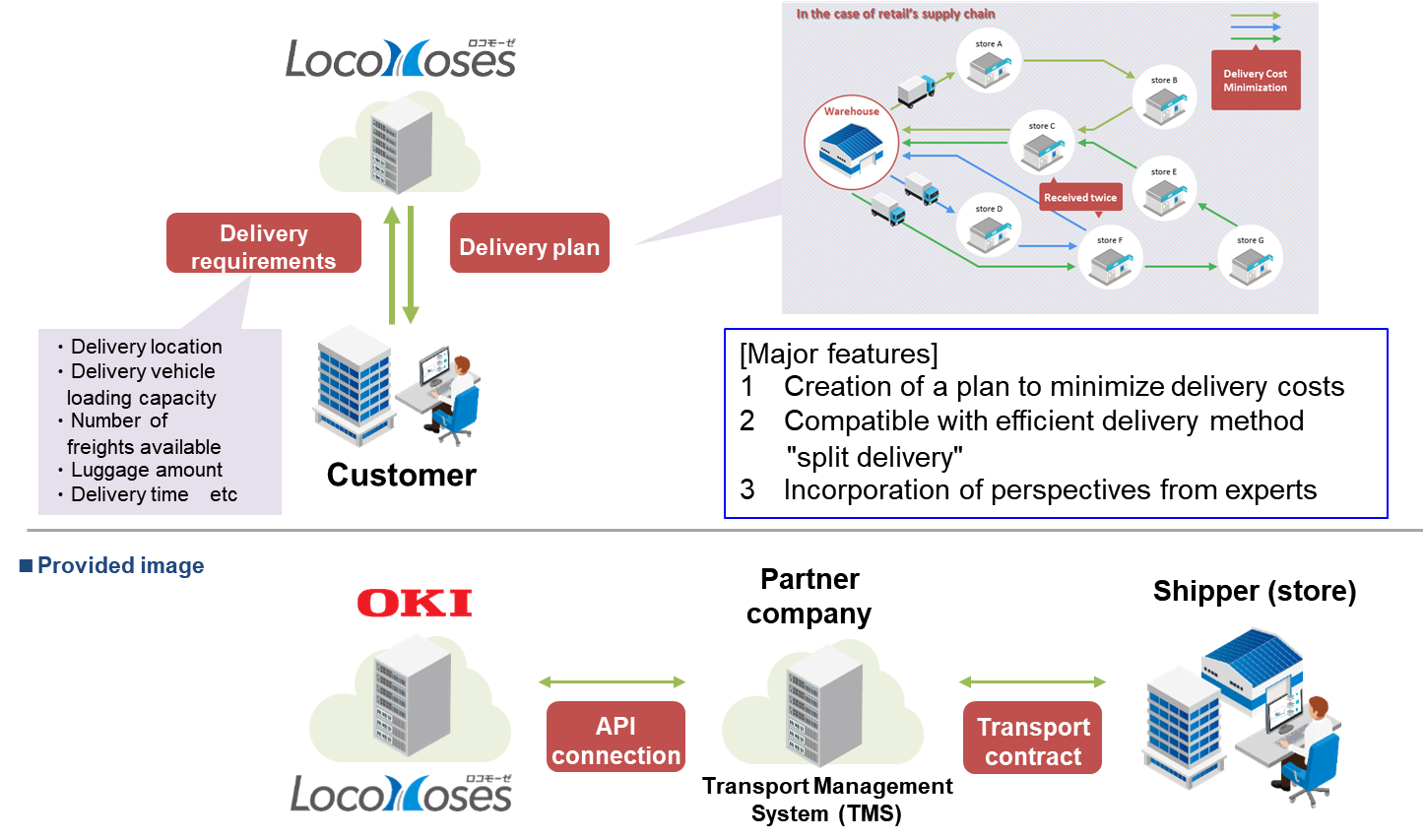

"LocoMoses" delivery planning optimization service.

- Automatically creating a delivery plan by inputting delivery requirements into the transport management system (TMS) ⇒ Showing the optimal solution in a few minutes

- With these three features, anyone can create delivery plans that are at least as good as those of an expert in a short time. ⇒ Reduction of transportation costs

Use case

Actively involved in building delivery networks for store deliveries and daily truck allocation operations

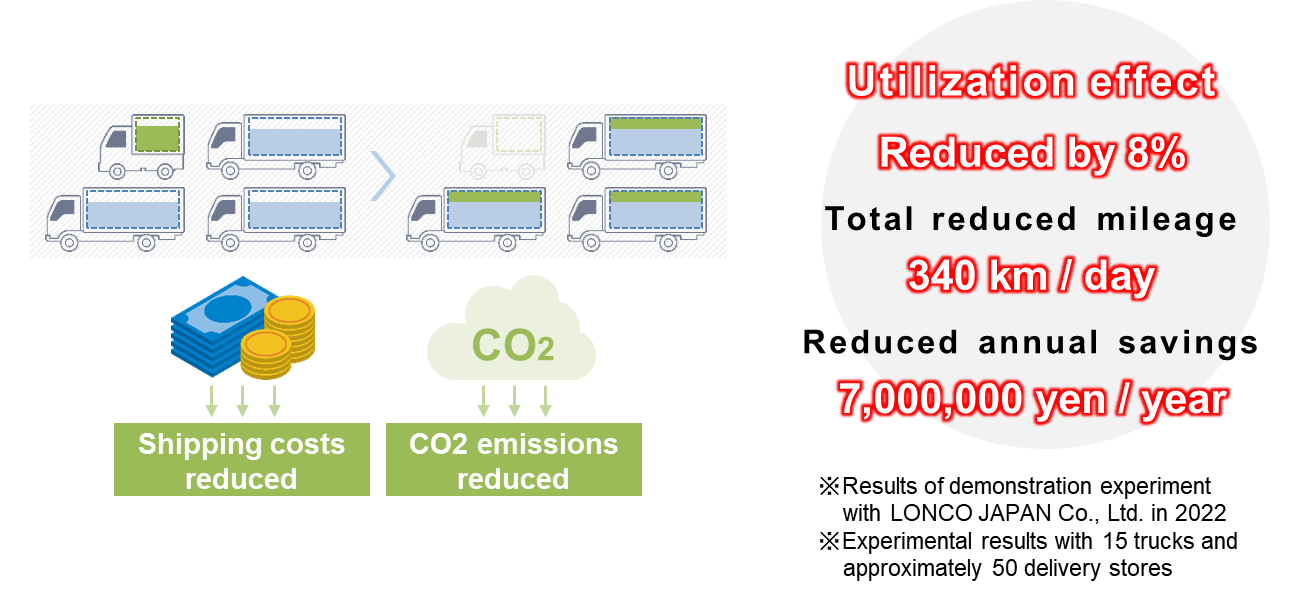

- We have started demonstration experiments with LONCO JAPAN Co., Ltd. from 2021, and launched providing services in May 2023.

- Costs reduced by 8% (fuel costs + expressway tolls) compared to delivery plans created by experienced dispatchers

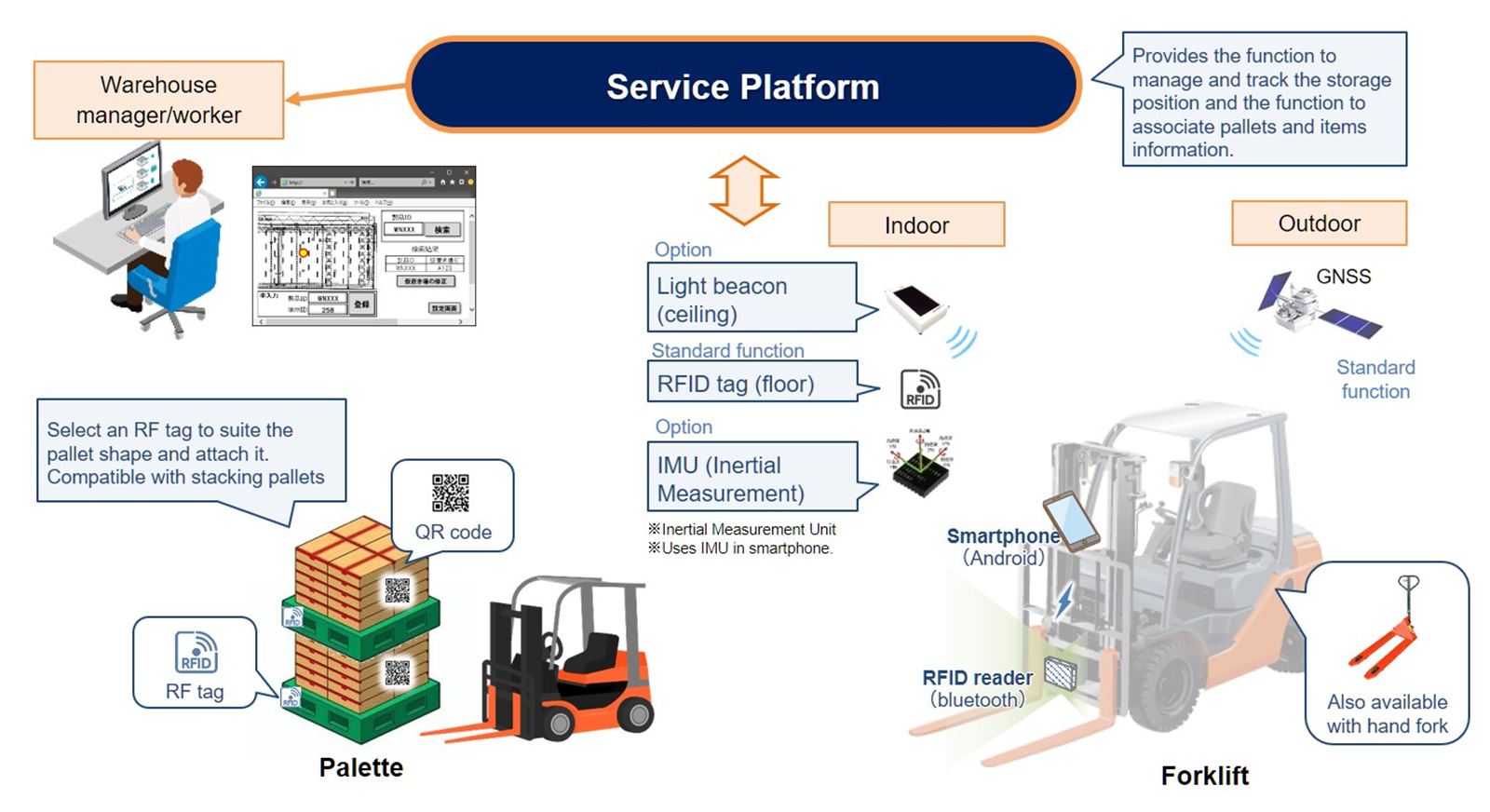

Automatic items positioning system

- Provides a solution that automatically records the package storage location, regardless of whether it is indoors or outdoors, using RFID tags/QR codes.

- As for the positioning information measurement method, GNSS (Global Navigation Satellite System) is used outdoors, and RFID (Radio Frequency Identification) tags, optical beacons, or IMU(Inertial Measurement Unit)* are used indoors.

- Realizes a system that can be introduced regardless of the usage situation by retrofitting the required devices to forklifts and other vehicles.

Use case

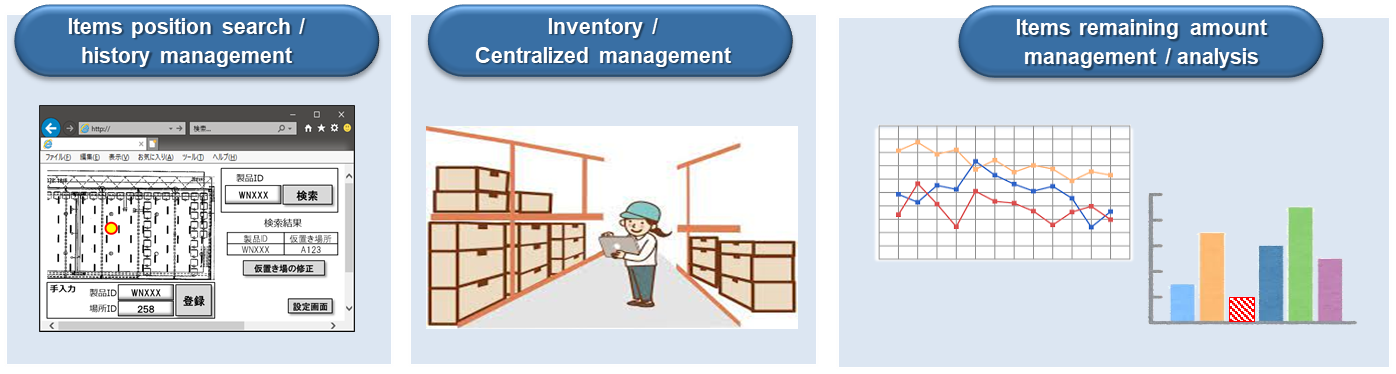

Improving the efficiency of warehouse operations

- Useful for picking and rearranging within the warehouse using the incoming/outgoing delivery time management function in addition to searching and displaying the items storage location.

- Reduced inventory work man-hours with automatic inventory and centralized management function using RF tags/QR codes.

- Managed the appropriate quantity of packaging by analyzing the remaining quantity of packaging and using the alert function if the amount falls below a certain level.

Future Initiatives in the Logistics Field

In the future, in the logistics field, we will work with co-creation partners to conduct the business development and market cultivation, with the aim of realizing and expanding solutions for each of transportation and warehousing.

We are looking for a wide range of co-creation partners, including co-creation partners who are aware of sector-related issues, as well as co-creation partners who are involved in sales focused on expanding the business in response to these issues.