- Home

- Innovation (Yume Pro)

- Activity Examples in Focus Areas

- We are looking for co-creation partners who can overcome the 2024 problem with technology.

Activity Examples in Focus Areas

Logistics

Do you have any of these issues?

- It takes time to create delivery plans. Know-how is individualized, so it cannot be passed on

- Even if you take the time to create delivery plans, you will not be able to create an efficient route

- The law revision due to take place in 2024 is approaching, but no solution has been found

Truck transportation is facing a number of problems, including a declining and aging driver population, reduced working hours due to tightening regulations (2024 problem), rising fuel costs, and declining truck loading rates due to an increase in small-lot transportation.

It has been pointed out that if appropriate action is not taken immediately, logistics may collapse after 2024, which is when regulations will be tightened.

The key to improving logistics efficiency is to create a delivery plan.

Until now, delivery plans have been created based on intuition and experience. Of course, these specialized skills are wonderful, however, there is also a risk that the work will become individualized.

Additionally, a delivery plans based on hunches and experience may not always be efficient due to ever-changing road conditions.

Some transportation companies may try to keep the total travel distance and the number of vehicles to a minimum by dividing packages into multiple freight loads rather than transporting them all at once.

Even in these situations, it is necessary to consider many requirements such as loading capacity, number of vehicles, and delivery distance. So as a matter of fact, it is difficult even for the most skilled personnel to formulate a stable plan.

Resolution using digital technology

In response to these issues that the logistics industry is facing, OKI has developed an algorithm that uses AI to automate the creation of delivery plans.

This enables you to create delivery plans that take into account on-site delivery know-how, such as "Should I deliver all at once or divide freight loads?", "Determining whether to use toll roads", or "Exclusion function for arbitrary combinations of delivery destinations" that are difficult to use with existing delivery software.

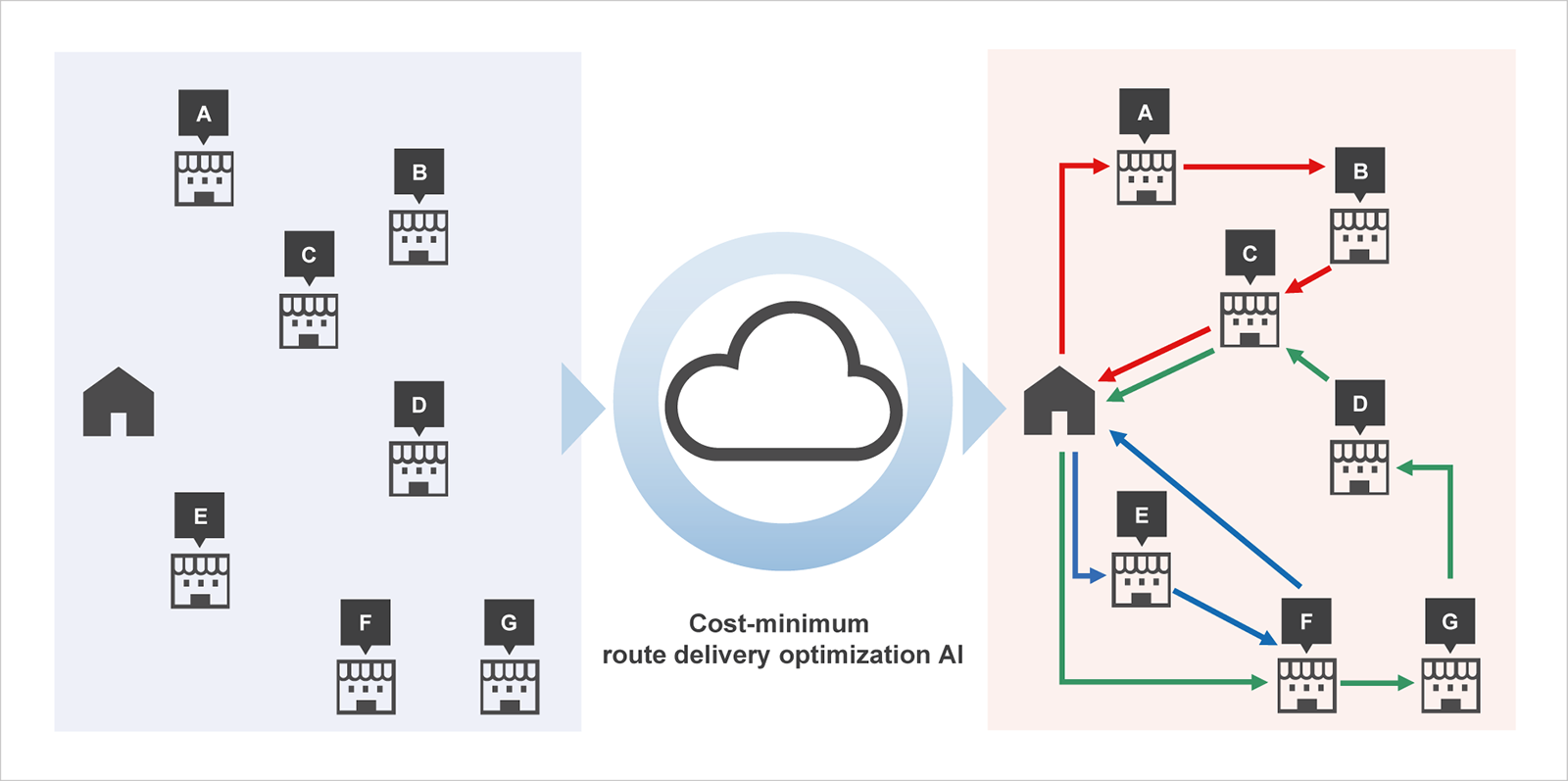

Here, we introduce the functions of the cost-minimum route delivery optimization AI.

Creating an AI-based delivery plan

The OKI delivery planning automation algorithm utilizes AI technology.

Once you enter your delivery requirements, the system calculates the optimal route that minimizes costs, taking into account factors such as the delivery destination and load capacity.

Also, even for complex delivery plans that combine bulk and split deliveries, it is possible to automatically create an optimal plan.

By increasing the precision of optimal planning using the algorithm, we can avoid situations where the quality of a delivery plan is determined by the difference in experience between veterans and newcomers.

By increasing delivery efficiency, on-site man-hours can be used more effectively, and the number of delivery projects can be expected to increase.

Benefits obtained from cost-minimum route delivery optimization AI

The benefits that can be obtained from the cost-minimum route delivery optimization AI can be broadly classified into the following five types.

Reduction of the time it takes to create delivery plans

Even delivery plans comprising complex conditions are calculated automatically by the algorithm, thereby, enabling you to significantly reduce the time it takes to create delivery plans.

You can create a truck allocation table simply by entering delivery requirements, so you can quickly create a high-quality delivery plan even when experienced staff are unavailable.

The point that you can always create stable delivery plans without depending on the individual will be one of your company's competitive advantages.

Elimination of the occupancy rate disparity between drivers

The delivery planning automation algorithm can equalize the load capacity and work time allocated to each truck.

The improved efficiency of the delivery process also leads to preventing delivery delays and delivery errors, contributing to improved service quality.

It also helps improve the working environment by reducing the burden on certain drivers, preventing accidents caused by fatigue and stress, and reducing a health damage.

Workplaces with good working environments tend to attract talented people, leading to improved competitiveness.

Reduction of toll road user charges

The system automatically determines whether you should use toll roads or whether there is no problem with regular roads, and incorporates the results into the delivery plan.

In addition, by setting rules regarding toll roads in advance, you can specify whether to use expressways or local roads for each section.

In a demonstration experiment, using this function resulted in a cost reduction of nearly seven million yen per year, including fuel costs.

CO2 reduction effect

The cost-minimum route delivery optimization AI can shorten the travel distance, so it is also possible to reduce CO2 emissions. The demonstration experiments show there is a CO2 reduction effect of approximately 440 kg per year.

It is also possible to engage in "carbon-free management" in line with the government policy of aiming for zero greenhouse gas emissions by 2050.

Expansion of your business

The improved efficiency of delivery planning also leads to business opportunities.

If you can shorten the flow from receiving a delivery request from a shipper to creating a delivery plan, you can take on more work.

As mentioned above, the delivery costs are also reduced, which leads to improved profit margins.

These become your strengths, which will contribute to business expansion.

OKI's Strengths

Optimization by quantum computer

The core of the OKI delivery planning automation algorithm provides a long track record of developing AI technology.

In the delivery planning automation, for example, AI determines whether to use expressways. Previously, the driver determined whether to use expressways based on the situation. However, when making judgments based on personal experience and intuition, delivery times will vary depending on the driver. This created a major risk when veteran staff members took time off.

If AI makes judgments that are comparable to those of experienced staff, it is possible to provide more stable deliveries.

This is a strength that can only be provided by OKI, which has been researching AI technology for many years.

Case study

Demonstration experiment with LONCO JAPAN Co., Ltd.

OKI is conducting a demonstration experiment using the delivery planning automation algorithm with LONCO JAPAN Co., Ltd.

In the experiment conducted in February 2021, we compared the plan created by the same algorithm with the plan created by experienced delivery planning professionals. As a result, it was confirmed that the algorithm-based plan reduces the 13-truck travel distance by approximately 300 km per day.

With the effects of the delivery time adjustment program added later, we were able to save nearly seven million yen annually in total fuel costs and expressway usage fees.

We also obtained data highlighting that CO2 emissions can be expected to be reduced by approximately 440 kg per year.

| Travel distance | Reduced approximately 300 km per day (total value for 13 trucks) |

| Cost | Reduced by approximately seven million yen per year (fuel costs + expressway usage fees) |

| CO2 | Reduction effect of approximately 440kg per year (estimated) |

Based on the co-creation with LONCO JAPAN Co., Ltd. we have started selling the cost-minimum route delivery optimization AI as a SaaS service called "LocoMoses". This service is provided integrated into the partner's truck allocation system.

Would you like to utilize OKI technology to solve the 2024 problem?

OKI aims to create innovation and build businesses together with companies that will become co-creation partners.

Rather than OKI unilaterally providing the solutions we have introduced above, we would like to improve them by combining the technologies and ideas of our co-creation partners.

"I'm still at the idea level, but I'd like to discuss what I can do."

"We would like to explore what we can do with OKI using our own technology and products."

Feel free to ask us at any stage you are at.