Products & Services

OKI and Netmarks Indonesia to Deploy Projection Assembly System™ to Indonesian Market to Help Eliminate Production Site Errors

Oki Electric Industry Co., Ltd. |

Partnership agreement signed to strengthen the realization of smart factories in Southeast Asia

Takashi Nakasendo, Managing Director, OKI Data (Singapore),

Shotaro Nakatsu, Executive Officer and

Head of the Enterprise Solutions Division, OKI,

Taofik Hidayat, President Director, Netmarks Indonesia,

Hideto Sasaki, COO, Netmarks Indonesia,

Ng Kim Soon, Director, Netmarks Indonesia

TOKYO, July 14, 2025 -- Oki Electric Industry Co., Ltd. (Head office: Minato-ku, Tokyo; Representative Director and CEO: Takahiro Mori; "OKI" hereinafter) and PT. Netmarks Indonesia (Head office: Jakarta, Indonesia; President Director: Taofik Hidayat; "Netmarks Indonesia" hereinafter) signed a partnership agreement on July 14, 2025, to expand adoption of the Projection Assembly System™ within the Indonesian market. The system helps eliminate production site errors. OKI will draw on this partnership to strengthen its sales channels and customer base in the market, and accelerate deployment of the system. Netmarks Indonesia will provide one-stop services from local sales to introduction assistance and maintenance support. The two companies' joint efforts will help resolve challenges facing manufacturers in Indonesia, including the need to improve production efficiency and standardize quality.

Indonesia has many production facilities in the automotive, auto parts, and electronics and electrical equipment industries that involve multiple assembly processes and require work know-how and skills. Economic growth has led to the need to improve factory production capacity and ensure quality that meets international standards. However, ensuring consistent workforce quality, enhancing employee training, and increasing work efficiency remain major challenges.

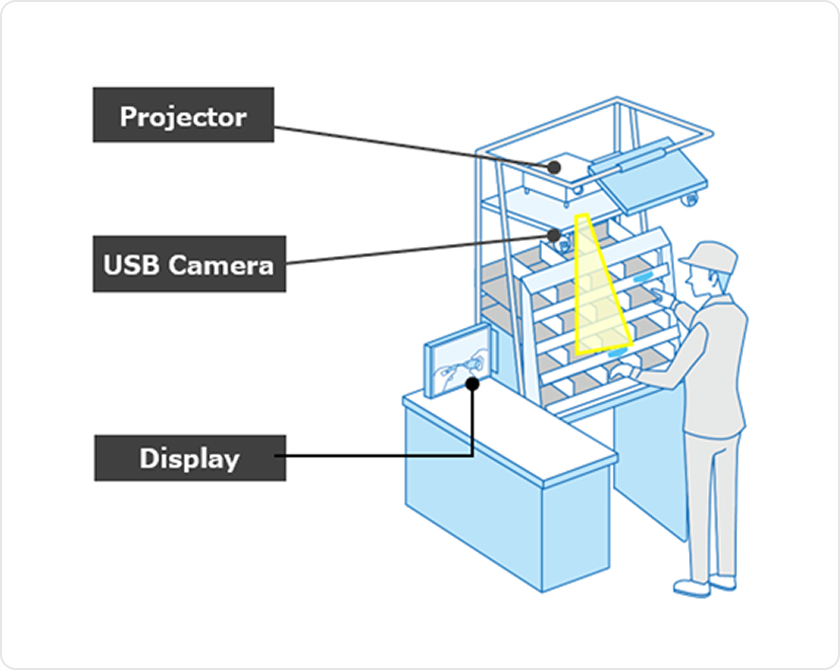

Features of the Projection Assembly System

- Eliminates work errors

Provides clear instructions for picking parts and displays work instructions and videos using a projector. - Digitizes work results in data form

Saves part picking results and videos captured during work as records. - Visualizes problem areas

Clarifies tasks and processes that create bottlenecks and identifies inefficiencies based on work videos.

OKI's Projection Assembly System is a solution that supports "site transformation" as part of Manufacturing DX (*1), which aims to realize smart factories. It combines projection mapping and image sensing technologies, and has been adopted by many manufacturers in Japan to help eliminate production site errors. Netmarks Indonesia has built robust sales channels and an established customer base for over 20 years in IT solutions sales, construction, and maintenance in Indonesia. It also provides a solid local support structure.

The partnership agreement will allow the two companies to build a comprehensive service system for the Indonesian market, from sales to introduction assistance, operation, and maintenance of the system, providing high-quality support tailored to local needs. The partners plan to expand into Southeast Asia to boost support for the realization of smart factories.

Shotaro Nakatsu, OKI Executive Officer and Head of the Enterprise Solutions Division, commented that Indonesia is a very important market for OKI's global business development and that he is looking forward to the joint creation of new businesses for the future, seeing this partnership agreement as a new start for both companies.

Taofik Hidayat, Netmarks Indonesia President Director, commented that with over 20 years of experience in delivering IT infrastructure support—including sales, implementation, and maintenance—in the Indonesian market, we are pleased to announce our partnership with OKI. Through this collaboration, we look forward to developing new proposals for businesses throughout Indonesia. Moving forward, we are committed to promoting "Manufacturing DX" to support the realization of smart factories in Indonesia.

OKI and Netmarks Indonesia plan to continue strengthening joint efforts and to help resolve a wide range of challenges facing manufacturers in Indonesia and Southeast Asia. OKI also plans to expand into other Global South countries in the future, assisting in the development of local industries and communities.

Terminology

- Manufacturing DX

OKI's solution concept for the realization of smart factories is comprised of three types of innovation: "site transformation" to make manufacturing sites visible; "IT/operation transformation" to provide high-level and two-way collaboration between site and management; and "management transformation" to support various management decisions such as environmental changes, legal compliance, and low-volume value-added production.

Related link

About Oki Electric Industry (OKI)

Founded in 1881, OKI is Japan's leading information and telecommunication manufacturer. Headquartered in Tokyo, Japan, OKI provides top-quality products, technologies, and solutions to customers through its Public Solutions, Enterprise Solutions, Component Products, and Electronics Manufacturing Services businesses. Its various business divisions function synergistically to bring to market exciting new products and technologies that meet a wide range of customer needs in various sectors. Visit OKI's global website at https://www.oki.com/global/.

- Oki Electric Industry Co., Ltd. is referred to as "OKI" in this document.

- Projection Assembly System is a registered trademark of Oki Electric Industry Co., Ltd. in Japan.

- All other company names and product names mentioned in this text are generally the trademarks or registered trademarks of their respective companies.

* Information in the press releases is current on the date of the press announcement, but is subject to change without prior notice.